From Kirby to R2-D2: Engineering student inspires others with 3D Printing Club

Tactile clicking can be heard around the classroom as 33 students peer at their computer screens.

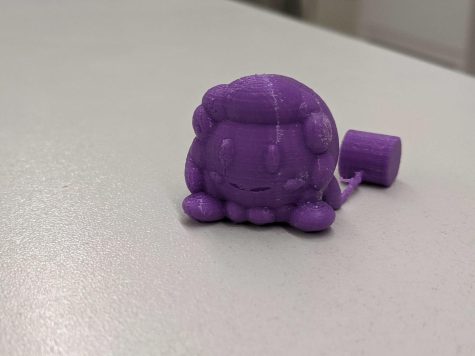

Each screen shows a visual model representation of a popular, round Nintendo character named Kirby being rendered in real-time by 3D modeling software.

While some students review their models, others help anyone struggling with the intricate software. Club President and founder Joseph Dean is eager to help his fellow club members.

For Dean, the need to help others inspired the club’s inception.

“I wanted to teach 3D printing to people who are intimidated by 3D printing,” Dean said.

The 22-year-old mechanical engineering major said the club officially began a week before the fall 2022 Club Rush event, held from Sept. 13 -15.

Before the club’s official creation, Dean taught people how to 3D print for the first time.

“It started out as a few friends,” Daniel Anttila, club supervisor, said.

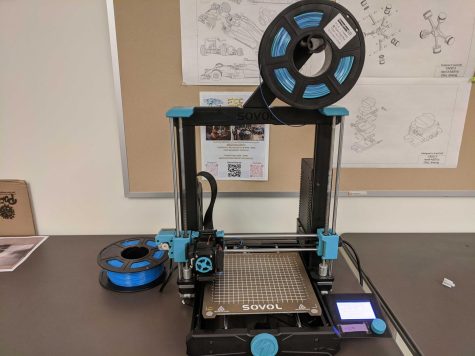

Dean and his friends would create 3D-printed models using the Makerspace lab located in the east basement of Schauerman Library.

Anttila instructed 3D modeling using Computer-Aided Design, a core foundation for creating 3D printed models. Such Computer-Aided Design programs include Fusion 360, Tinkercad and Blender.

However, Anttila said having experience with Computer-Aided Design programs is not required to join the club because premade model files can be found online.

Club members are encouraged to engage with the software to create more personalized printed items.

Another important piece of software is a program called a slicer, which helps translate the 3D model file into code that 3D printers can use to create displayed models. Specific slicers used in the club include KiriMoto, Cura and PrusaSlicer.

Programs are only half of the process as applied manufacturing is involved in the creation process to mold an accurate 3D printed model.

Although the club contains printers, not in active use, Anttila said club members often prefer to work with their home brought equipment.

Fire and Emergency Technology major Anthony Carlos would have never heard about the club without a friend’s recommendation.

Carlos showed optimism about the positive future impact of the club, as the lessons in 3D modeling could help him further his career in fire tech.

As for the club’s future, Dean expressed aspirations to continue expanding beyond the scope they are currently operating at.

Dean said the club had already attended a few events and collaborated with the robotics club to create a 3D printed shell for one of their robots modeled to resemble R2-D2 from the “Star Wars” franchise.

Although she had prior experience with 3D modeling, Mechanical Engineering major Emily Lavelle said the club allowed her to learn different programs she had never used before to 3D model.

“I think it’s a good club for STEM majors,” Lavelle said. “It’s a good skill to learn.”

![Physics and astronomy professor Susan Stolovy presents astronomical news and updates to attendees at the first planetarium show of the semester at El Camino College on Friday, March 28. Prior to becoming a professor at ECC, Stolovy completed her doctorate in physics and worked as an astrophysicist for NASA and the California Institute of Technology on spacecraft missions. "[I'm] still very tuned into what's going on in the world of research as well, and I hope to bring a little bit of my experience into the classroom," Stolovy said. (Nikki Yunker | The Union)](https://eccunion.com/wp-content/uploads/2025/03/planetarium-Made-with-Clipchamp-3-frame-at-0m28s-600x338.jpg)