As the flame from a blowtorch touches the metal, they begin to heat it into shapes, hammer it together and then bend it into artwork in Shop Room 100, a welding class teaching students different processes of welding.

“They burn and bend metal to shape their artwork by using five different welding processes,” Renee Newell, the newest welding professor said. “They are called annealing, tungston inert gas, shielding metal art, flecore art, and gas metal art welding (MIG).”

Welding has become a field in demand with classrooms full of students that are eager to learn, Newell said.

“The reasons students take welding classes are usually for certification purposes, more specifically for the D1.1 (structural steel certification),” Newell said. “President Barack Obama is currently making a drive with a program in the field to push for more skilled welders.”

According to The Career Advancement Academy. Theplan is train workers in the welding field for 2014, where there is going to be a lot of retiring welders in the field. Obama will demand 580,000 new welding workers, Newell said.

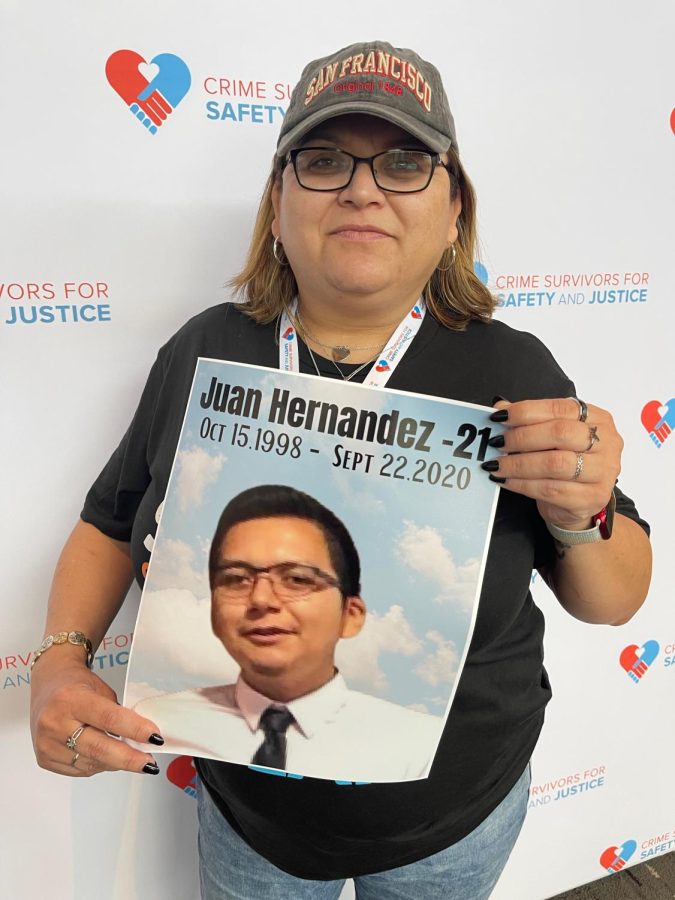

Newell is presently working with the CAA program, where she is helping students weld hearts to exhibit in the Schauerman Library this month for at-risk youths who have gotten in trouble and are trying to turn their lives around.

“I’m pleased to be a part of such an awesome program,” she said.

Professor Samuel Dantzel said welding has become very popular among students because it is in everyday construction.

“Shield Metal Art and MIG welding are common in buildings,” he said. “Aerospace and car enthusiasts also use gas Tungston welding.”

Dantzler said the welding department offers two different programs.

“We have the day program and the night program,” he said. “In the day we use all the processes over the four semesters and in the night program, students can specialize in whatever process they want.”

Dantzler said welding could be dangerous so it’s required that all students have a mask and a pair of gloves before using their tools.

“We use many types of tools such as a welding machine, an electrode, an electrode holder, and a flaming blowtorch,” he said.

Fortunately they have a shop technician, Matt Hutcherson, who works very closely with the tools.

“I hand out and check in tools to students. The tools tend to get really expensive,” Hutcherson said. “Thankfully, federal grants pay for pretty much everything.”

Some students really look forward to coming to class and using their tools to weld.

“I love how we have so many tools,” Jacob Narsha, 24, art major said. “My favorite tool to use is the blowtorch.”

Narsha said he hopes to make welding into a profession one day.

“I don’t see why not. Nearly everything we use is welded or made by equipment that is welded.” he said. “In construction, welders are virtually rebuilding the world.”